Main Menu

- Home

-

-

- Bristle Brushes

- Bur Holders

- Cutting Discs & Wheels

- Diamond Discs

- Diamond Polishers

- Diamond Stones

- Fg Carbide Burs

- Fg Diamond Burs

- Hp Carbide Burs

- Hp Diamond Burs

- Mandrels

- Mounted Stones

- Mounted Polisher

- Plaster Cutting Discs

- Rubber Wheels Crbr

- Rubber Wheels Crco

- Rubber Wheels Prosthetics

- Rubber Wheels Universal

- Soft Base Trimmers

-

- Attachments & Posts

- Block Out Opaque & Seal

- Cements

- Ceramic Brushes

- Ceramic Instruments

- Ceramic Trays

- Ceramic Tray Accessories

- Ceramics

- Colouring Liquids

- Composites

- Die Hardeners

- Die Separators

- Die Spacers

- Firing Trays & Support

- Injection Moulding

- Investment Crbr

- Metal Alloy Crbr

- Occlusal Moulds

- Pin & Base Model Systems

- Plasticizers

- Polish & Finishing Aids Crbr

- Prime & Bond

- Resins

- Rubber Wheels Crbr

- Shade Guides

- Soft Tissue

- Soldering

- Stain & Glaze

- Temp Acrylic

- Wax Crbr

- Implant

- Our Collection

Description

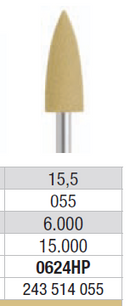

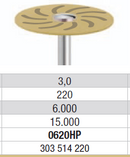

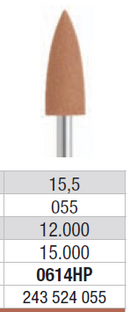

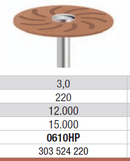

Exastar polisher for polishing PMMA materials

Specially developed 2 step polishing system with hybrid grit and matrix binder for the reliable and gentle polishing of thermoplastic PMMA materials. Careful polishing reduces plaque accumulation and is thus a prerequisite for good aesthetics. After milling the PMMA restoration in the CAD/CAM machine, the surface roughness must be reduced. ExaStar polishers guarantee a finish and glaze polish for an optimum surface lustre. The new polisher matrix in combination with the hybrid grit enables an optimum surface polish without the use of polishing paste. Polishing easily and quickly produces an aesthetic result, so that the PMMA restoration can be fitted immediately after polishing.