Main Menu

- Home

-

-

- Cad-Cam Accessories

- Cad-Cam Consumables

- Cad-Cam For Clinics

- Colouring Liquids

- Firing Trays & Support

- Glass & Hybrid Ceramics

- Metal Milling Discs

- Milling Unit

- Milling Burs

- Pmma For Milling

- Scanner

- Scan Spray

- Software

- Stain & Glaze

- Wax For Milling

- Zirconia Amann Girrbach

- Zirconia Open

- Zirconia Sirona

- Zirconia Zirkonzahn

-

- 3D Light Cure & Cleaning

- Articulators

- Articulator Accessories

- Bunsen Burner

- Chisel

- Chisel Accessories

- Denture Cleaning Unit

- Denture Cleaning Unit Accessories

- Electrolytic Polisher

- Equipment For Clinics

- Extraction Unit

- Extraction Unit Accessories

- Flexi Machine

- Flexi Machine Accessories

- Furnace Burn Out

- Furnace For Ceramics

- Furnace For Sintering

- Furnace Accessories

- High Speed Grinder

- Hydraulic Press

- Light Curing Unit

- Micromotor

- Micromotor Accessories

- Milling Unit

- Milling Unit Accessories

- Model Arch Trimmer

- Model Arch Trimmer Accessories

- Model Trimmer

- Model Trimmer Accessories

- Other Equipment

- Pin Drill System

- Pin Drill System Accessories

- Plaster Trap

- Plaster Trap Accessories

- Polishing Lathe

- Polishing Lathe Accessories

- Polymerisation & Boil Out

- Polymerisation Accessories

- Sandblaster

- Sandblaster Accessories

- Scanner

- Steam Cleaner

- Steam Cleaner Accessories

- Surveyor

- Ultrasonic Cleaner

- Ultrasonic Accessories

- Vacuum Former

- Vacuum Former Accessories

- Vacuum Mixer

- Vacuum Mixer Accessories

- Vibrators

- Visual Aids

- Visual Aids Accessories

- Wax Heating Unit

- Wax Heating Unit Accessories

- Welding Soldering & Casting

- Implant

- Our Collection

Description

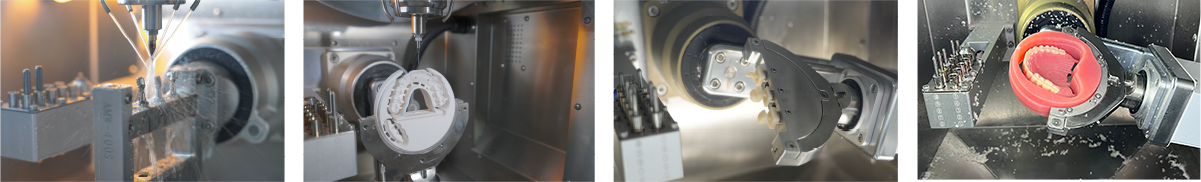

AMM-520

Wet & Dry Milling machine

[ Introduction ]

AMM-520 is a wet and dry integrated multi-functional milling machine, with a stable structure and a variety of fixture combinations, meeting different production needs.

[ Aidite AMM-520 Highlights ]

Machine Maintenance Tips

Safety Door

one-piece silicone

Customized Abutment Reverse Grip Milling

Harmonic drive

Various fixtures (optional)

[ Parameter ]

Machine size |

590×730×820(mm); |

Weight |

180Kg |

Tool changer |

10 |

Number of axes |

5 Simultaneous Processing |

Milling mode |

Wet and dry |

Material thickness |

10-35mm (round disc) |

Accessories |

Work table, water cooler, water tank |

Repeat positioning accuracy |

± 5um |

Linear drive system |

Linear guide and lead screw |

Rotary drive system |

Harmonic reducer |

Control system |

Embedded CNC system and AC bus servo motor |

Millable material |

Zirconia, PMMA, HPP, PEEK,Titanium disc, wet milling restoration material, denture, premill |

Processing time |

Single crown ≤15min, Premill ≤20min Wet milling restoration material≤20min, full denture≤3h |

[ Spinde ]

Power: AC 1500W

Cooling: water cooling

Speed: 60000rpm

Chuck size: Φ4 mm

[ Function ]

Power supply:

single-phase AC 220V 50/60Hz Voltage

Power: 2.2KW 10A

Air pressure: 6Bar

[ Processing type ]

Denture, bitesplingt, snap on smile, surgical guide, partial framework, crown and bridge, veneer, inlay, post and core, screw-retained bridge (a separate nesting moudle needs to be added for implant case), custom abutment

[ Detail Effect ]